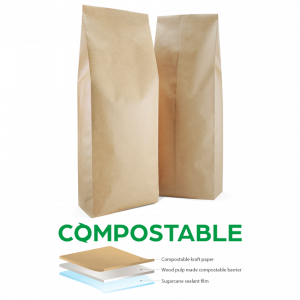

Compostable Coffee Packaging

Our compostable coffee bags are crafted from high-quality, certified materials, designed to break down in less than 90 days in commercial composting environments per EU standard EN13432. Although achieving full home compostability certification for the entire bag remains a challenge due to its sophisticated high-barrier properties, each layer within the NKME bags meets home compostable standards.

For those preferring a traditional look, our Kraft paper finish offers an aesthetically pleasing, eco-friendly packaging solution. Alternatively, our matte PLA bags provide a sleek, modern appearance while maintaining the benefits of compostability.

If you are interested in custom printing don’t hesitate to contact our team.

Key Takeaways

- Commercial Composting: Our compostable bags decompose within 90 days in commercial facilities, adhering to EU standard EN13432.

- Material Options: Available in eco-friendly Kraft paper or matte PLA, catering to diverse business needs.

- Customization: We offer custom printing options to tailor products to your branding.

- Material Insights: NKME/NatureFlex films provide excellent preservation qualities, beneficial for flavor and freshness.

Filter by

Category

-

Box Bottom

-

Side Gusset

-

Stand Up Pouches

-

Flat Pouches

-

Cylinder

-

Other

Bag Size

Material

Colour

-

Green

-

Yellow

-

Natural (brown)

-

White

-

Black

-

Christmas

-

Copper

-

Gold

-

Grey

-

Red

-

Silver

-

Printed Kraft

-

Black/Clear

-

Clear

-

Tan

Valve

Zip

PLA compostable packaging

PLA: Derived from renewable resources like corn starch, sugarcane, or cassava. It’s a bioplastic made from lactic acid biodegradable under the right conditions. Industrially compostable but requires high temperatures not typically achieved in home composting environments.

Generally offers good barrier properties, though it might be more permeable to moisture and gases compared to some specialized films like NKME/NatureFlex.

NKME compostable packaging

NKME/NatureFlex: Designed to be compostable in industrial facilities and may also break down in home composting setups. It is made from renewable resources like wood pulp from managed plantations. It’s a cellulose-based film, biodegradable and compostable.

Known for excellent barrier properties against gases, oils, and aromas, making it suitable for preserving the freshness and flavor of food products.

Frequently asked questions

Compostable products and materials are not typically recycled in the same way that traditional recyclables such as paper, plastic, and metal are. Instead, compostable materials are designed to break down into natural, soil-like substances through the process of composting.

It’s important to note that compostable materials should not be placed in traditional recycling bins, as they can contaminate the recycling stream and interfere with the recycling process. Instead, they should be disposed of in a composting bin or taken to a commercial composting facility.

Industrial composting and home composting are two different methods for breaking down organic materials into compost.

Industrial composting occurs at specialized facilities where the conditions for composting are carefully controlled. These facilities typically have the equipment and resources needed to manage large volumes of organic waste, and the process is typically faster and more efficient than home composting. Industrial composting is also more reliable, as the conditions for decomposition are carefully managed to ensure that materials break down as intended.

Home composting, on the other hand, occurs at a smaller scale, usually in a backyard or other outdoor space. Home composting relies on naturally occurring microorganisms to break down organic matter, and the process can be affected by factors such as temperature, moisture, and the presence of air. Home composting can be a useful way to reduce waste and improve soil fertility, but it is not as efficient or reliable as industrial composting.

Both industrial and home composting have their own benefits and limitations, and the most appropriate option will depend on the specific needs and resources of the individual or organization involved.

Compostable materials are designed to break down into natural, soil-like substances through the process of composting. When properly composted, compostable materials should not leave any microplastics behind.

For industrial compostable products dispose of in the food waste recycling stream where this exists.

While we recommend to do the same with the bags made with home compostable materials, If you decide to compost our bags made with home compostable materials at home, here are some steps to follow:

- If the bag has a valve, please remove it. The valves are only industrially compostable and will not compost in the temperatures of a home compost.

- Add the product to the compost: break the product down into small pieces, if possible and mix with other organic materials.

- Monitor and maintain the compost: Keep the compost moist but not too wet and turn it regularly to aerate it and help it break down.

Keep in mind that the composting process can take several weeks or months depending on the size and type of the product. While the individual layers are certified for home composting in 90 days, the whole product might take longer depending on the temperatures and conditions.

All the materials out laminates are made for are as a minimum certified EN13432 industrially compostable.

Don’t hesitate to contact us for the certifications.

EN13432 is the EU standard for compostability. Products certified under this standard must meet stringent requirements for biodegradability, understood as the capability of the packaging material to be metabolically converted into carbon dioxide; disintegradability, understood as fragmentation and loss of visibility in the final compost (absence of visual pollution); and Absence of negative effects on the final compost, meaning that the compost should be good for growing food in.

This requires a complex answer. They do not contain what most understand as plastics, however PLA, Bi-PBS, NKME are all per definition plastics, even though they are generated from non-fossil sources. They are compostable and degrade into CO2 and water only, not leaving any micro-plastics behind.

EN13432 requires the compostable plastic to disintegrate within 12 weeks and completely degrade within 6 months. This means that at least 90% of the plastic material will be converted into CO2 within this period. The last up to 10% will have been converted into water and valuable compost.

Industrially compostable materials will only degrade under certain conditions, such as those found in an industrial compost heap. In nearly all other situations the materials will not degrade.